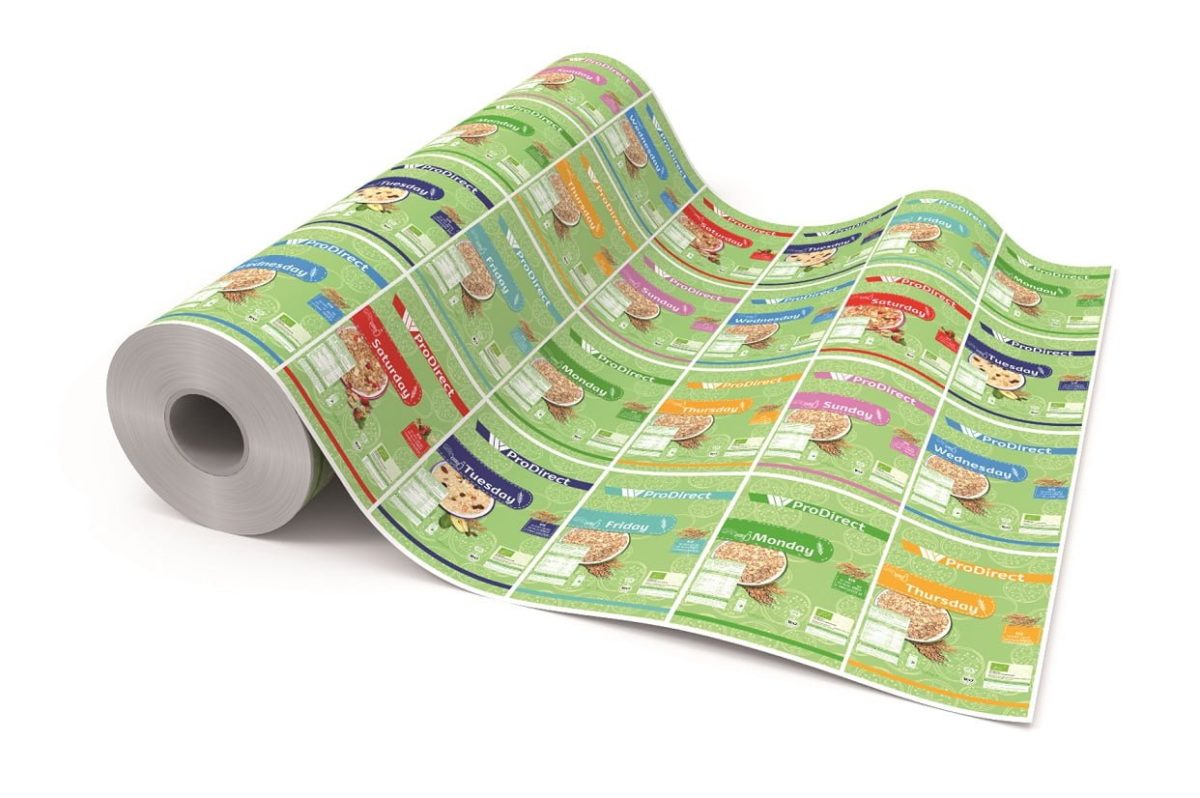

Called ‘ProDirect’ and premiered at this year’s Interpack, the concept is perfectly suited to producing small print runs in both an economical and a sustainable manner.

“Digitisation is quickly infiltrating all areas of a business, from purchasing to production, and logistics to sales and marketing,” said Enrico Riechert from the Business Development department at Wipak Walsrode. “Markets are currently undergoing major changes, with flexibility, speed, consistent levels of high quality, and economic efficiency all in great demand. We believe our ProDirect concept will boost the digitisation trend and set new standards.”

ProDirect is based on a new and unique printing technology, combined with optimized ordering processes and high-performance composite solutions.

“Print images can be personalized and adapted while the process is already running,” explained Riechert. “This is an enormous benefit for manufacturers who are active on different markets with a large range of products and regional brands. With ProDirect, they are now able to immediately respond to trends, customer requests and competitors by efficiently and ecologically producing small batch sizes, such as for seasonal or promotional items. Using ProDirect, our customers are getting the exact quantities they really need. This means enormous planning reliability.”

“In addition to our standard films, we also offer digitally printed paper laminates as part of our ProDirect concept,” he emphasized. “The sustainable material combinations, which include barrier layers against mineral oils, are attractive for many applications, and can help convey characteristics such as craftsmanship, health or nature as part of a product’s marketing strategy.”

“The performance of paper laminates is identical to the performance of pure plastic packages,” Riechert continued. “When used in combination with extremely low gauge high-barrier films, and laminated with solvent-free adhesives, it is even possible to package products under MAP conditions.”

The strong laminate structures also offer high puncture resistance, providing excellent protection against the migration of mineral oil residues or mineral oil-based printing inks in folded boxes.

The paper grades used for ProDirect are FSC®-certified, use 100% virgin fibres and have been verifiably sourced from responsible forestry.

Click here to visit our Interpack Campaign page!